Where are coupling coefficients of T Sai Wu theory. For applications in very corrosive services composite tanks and vessels can be produced with in a dual laminate configuration a fiberglass tank shell with a liner constructed of plastic.

Pdf Design And Analysis Of Composite Pressure Vessel Semantic Scholar

In order to reduce the thickness of the pressure vessel without affecting the performance of the vessel composite material were used.

. A number of factors must be taken into account in designing composite pressure vessels including the strength of the materials selected the effect of winding stability geometric. Type 3 COPVs from Advanced Structural Technologies Inc AST in particular feature a thin and lightweight 6061 aluminum liner fully overwrapped with carbon fiber composite. I need to repair cracks in of our pressure vessel and composite materials using PCC-2 code will improve the vessel integrity with minimum risk.

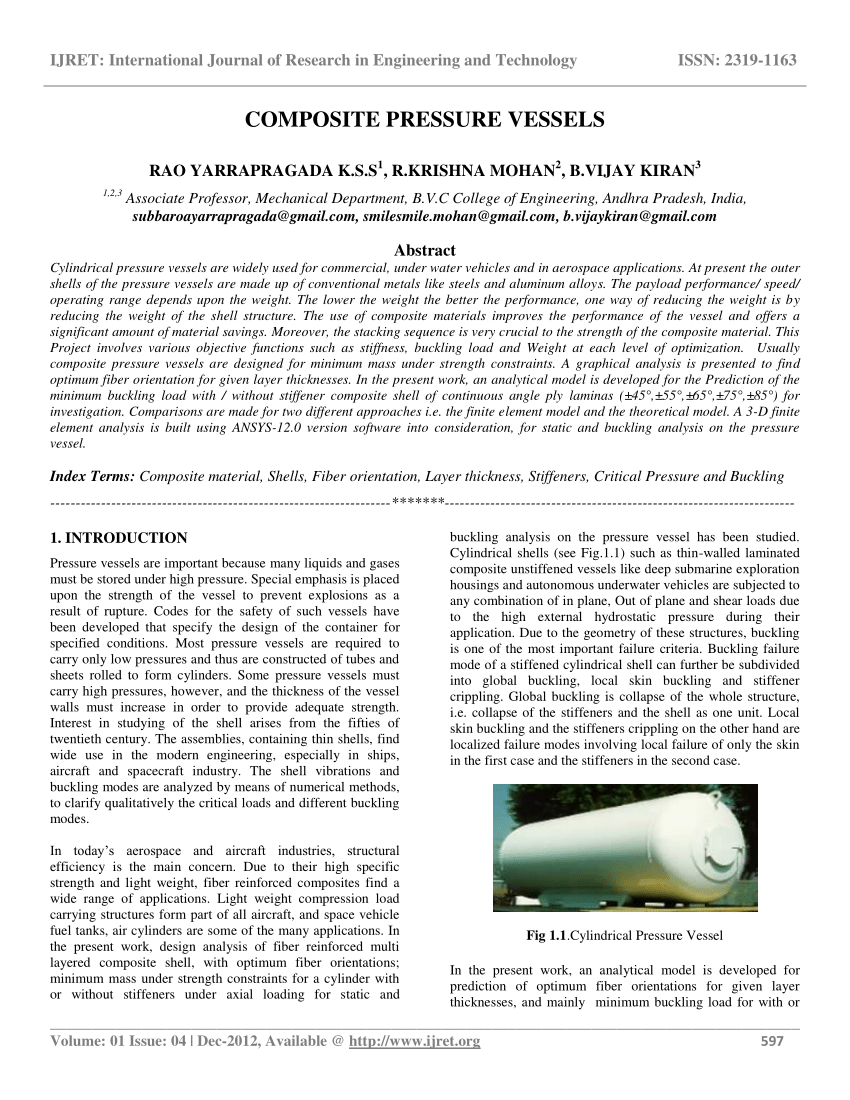

At present the outer shells of the pressure vessels are made up of conventional metals like Structural analysis will be done in ANSYS on the pressure vessel. The use of composite materials improves the performance of the vessel and offers a. The design of these parts is the most important issue for such vessels 32.

Industrially produced composite pressure vessels are made by filament winding tows of high strength carbon fiber over a mandrel which serves as a liner in the finished structure and serves to ensure gas tightness. First constructing pressure vessels in whole or in part from composites reduces fuel system and vehicle weight. Those shown in the figure above are the twelve sections of the code.

In todays aviation brass is the major element used for construction of pressure vessels It has high mingling properties which provide various properties. Typically pressure vessels are made of steel but there are some that employ composite materials such as carbon fiber ceramics and polymers like PET polyethylene terephthalate. Boiler and Pressure Vessel is divided into the following sections.

The composite materials carry the structural loads. These fluid-retention barriers may be a rubber plastic or thin ductile metal liner. A B 2 3.

The design of a pressure vessel is entirely reliant upon mechanics of materials. A graphical analysis is presented to find optimum fiber orientation for given layer thicknesses. A graphical analysis is presented to find optimum fiber orientation for given layer thicknesses.

These liners serve to. The geometry was verified through FEM analyses. The results reveal that designs exclusively based on shape and material parameters are in some cases far from optimal.

Usually composite pressure vessels are designed for minimum mass under strength constraints. Dear experts ASME PCC-2 is a post construction code for vessel repairs and alterations using composite materials. And if the criteria used is the inverse of strength index.

This project is proposed to analyse and design a cylindrical pressure vessel made up of composite material. Prediction of the ultimate strength of a designed vessel is done using various failure theories. Composite pressure vessels are designed for minimum mass under strength constraints.

The new composite material considered is waspaloy. The focus of this research is to evaluate the reliability of pressure vessels made of composite materials carbon and glass fiber with respect to stress and burst pressure. 7222 Characteristics of the Components in Composite Pressure Vessels.

Composite Pressure vessels design. On a typical transit bus or commercial truck for example the use of Type III and Type IV vessels easily could reduce the weight of the gas containment system by more than 1000 lb 454 kg. To properly design a pressure vessel it is necessary to understand Section VIII of course and additionally the designer will need to be familiar with Sections II V and IX.

Design according to T-Sai Wu failure criteria as given below. As the fiberresin composite is generally notconsidered pressure tight the composite is applied over a fluid-retention barrier that serves as an interior liner for the composite. Small thicknesses theory was adopted to sizing the components.

Cylindrical composite pressure vessels incorporating additional constraints like pattern consistency and strain compatibility at the cylinder dome intersection. 34 APDL Programming of Composite Pressure vessels. The stress values are less for steel material compare with CFRP Epoxy Resin.

The most notable pressure vessel construction standard is Section X of the ASME Boiler and Pressure Vessel Code. Composite pressure vessels tend to fail in their composite pressure vessels parts. Standard Custom Designs including Quick-Open ASME available Engineer Support.

Types I and II pressure vessels are those which are primarily metallic most often steel. Ad Designs Manufactures A Broad Range Of Pressure Vessels Reactors. Ad The Number 1 Source For Corrosion-Resistant Heat Exchangers Process Equipment.

While ASME Section VIII Division 1s design-by-rule approach is most commonly utilized by engineers to size the pressure vessel according to the application requirements it is. WEIGHT CALCULATION Table 1111 Weight calculation of pressure vessel SNo Material Density in Kgmm3 Volume in mm3 Weight in Kg 1 Steel 785x10-6 82x105 643 2 Composite 190x10-6 82x105 155 Percentage of weight reduction 643-1556431007589 643 By using the composite pressure vessel instead of steel pressure vessel weight has reduced to 7589 308. 3 Where 3 is the value of T Sai Wu failure criteria.

Composite pressure vessel was manufactured from fibers oriented 555555552s and the impact energies were chosen as 10 15 20 25 30 J for empty vessel during the impact tests. When building a pressure vessel out of composite materials some the theories employed to optimize strength and predict failure are the Tsia Hill energy-based interaction theory and maximum stress and. COPVs with advanced fibers and metal liners are classified as type 3 COPVs.

The composite materials chosen for modeling and analysis of pressure vessel are carbon.

Pdf Burst Strength Analysis Of Composite Pressure Vessel Using Finite Element Method Semantic Scholar

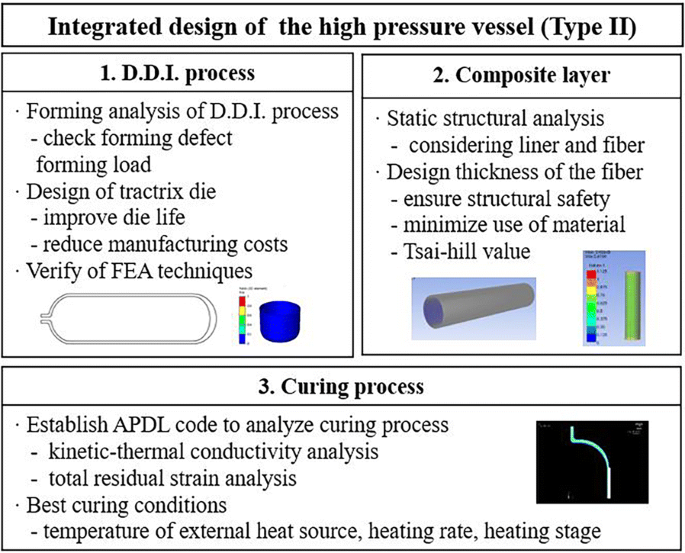

Integrated Design Of D D I Filament Winding And Curing Processes For Manufacturing The High Pressure Vessel Type Ii Chinese Journal Of Mechanical Engineering Full Text

Pdf Composite Pressure Vessels

Experimental Method And Numerical Simulation Demonstrate Non Linear Axial Behaviour In Composite Filament Wound Pressure Vessel Due To Thermal Expansion Effect Sciencedirect

Composite Pressure Vessel Design And Simulation

Advanced Aerospace Structures Lecture 4b Composite Pressure Vessel Netting Theory Youtube

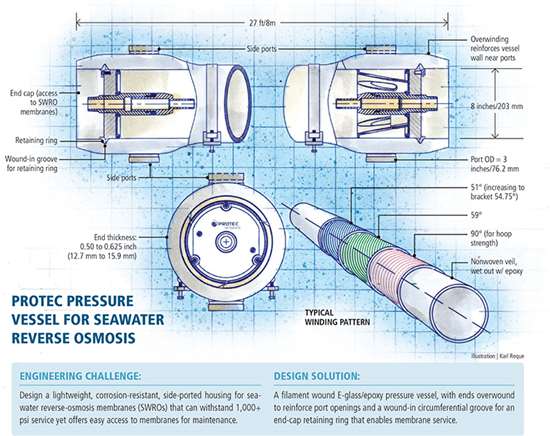

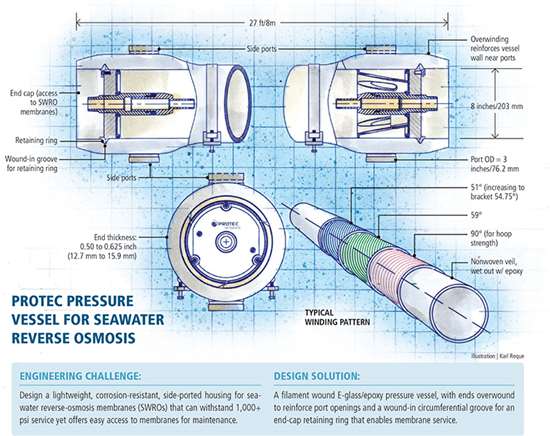

Designing Pressure Vessels For Seawater Desalination Plants Compositesworld

A New Concept For A Modular Composite Pressure Vessel Design Sciencedirect

0 comments

Post a Comment